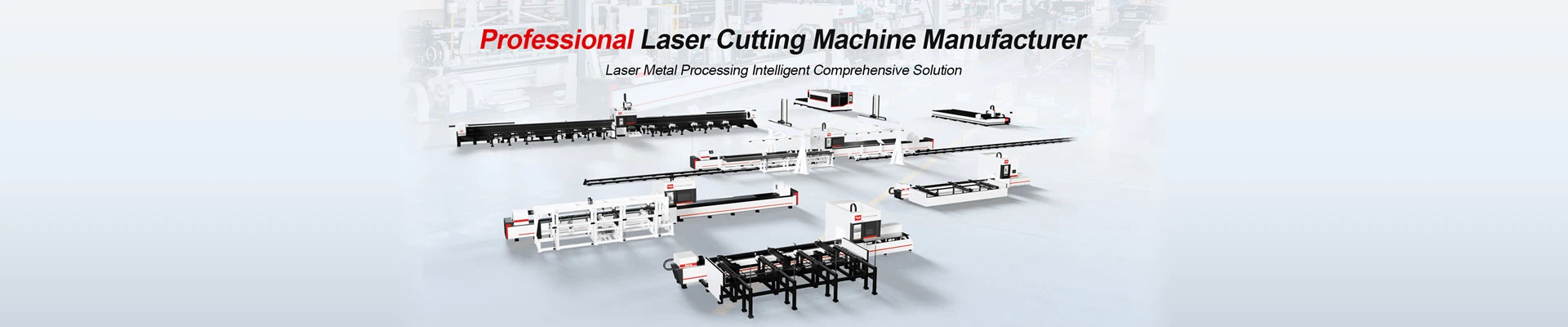

15kw pipe laser cutting equipment

0 tailing: reduce material waste, reduce production costs;

Support 3D bevel cutting: V-bevel Y-bevel X-bevel K-bevel and gradient cutting can be competent. Cutting section is good, no burr, processing accuracy meets the requirements tolerance. No secondary process: convenient for subsequent welding.

High power design used to cut a wide range of wall thickness, helping to reduce scrap and material costs.

How to process special-shaped tubes on 15kw pipe laser cutting equipment

Problem description:

There are two difficulties in processing special-shaped tubes. One is that the cutting head will hit the tube wall at the concave corners, and the other is that it is difficult to find the center, resulting in poor precision.

1. Edit the outline vector to solve the head collision problem

Using the <Edit Contour Vector> function, the vectors at the concave corners can be freely edited.

Processing according to the edited file can solve the problem of head collision at concave corners. (Note that the TubePro version must not be lower than 7.0.13)

2. Centering Method of Special-Shaped Tube

2.1. Use fixtures to ensure clamping accuracy

If you make a fixture specifically for a special-shaped tube to ensure that it is in the same orientation every time you clamp it, and you need a specific side of the drawing to face up, you can use the <Rotate Section> function to change the default orientation of the drawing.

For example, the special-shaped tube in the figure below has the long straight edge facing upward by default when imported.

Since the special-shaped tube is upright after being clamped by the fixture, if the tube orientation in the drawing is not changed, it is necessary to rotate the B-axis 90° and then set the current state to horizontal before each processing, which is quite troublesome.

By changing the orientation of the pipe through <Rotate Section>, it can be processed directly after each clamping.

2.2. Manual centering method using TubePro

If a custom fixture is not available, TubePro's Manual Centering or Advanced Manual Centering methods can be used to improve machining accuracy. For detailed instructions on how to use these functions, please refer to the TubePro section of the Knowledge Base.

Hot Tags: 15kw pipe laser cutting equipment, China 15kw pipe laser cutting equipment suppliers, manufacturers, factory, 3 chucks tube laser cutter, Automatic Tube Laser, Best Fiber Laser Cutting Pipe Machine, CNC Tube Pipe Fiber Optic Laser Cutting Machine, Laser pipe cutting machine, metal tube cutter